Optimising Lubrication and Scavenging Dynamics: Insights from Advanced CFD Modelling

Introduction: The maritime industry is under increasing pressure to optimise engine performance, reduce emissions, and comply with ever-tightening IMO regulations. HJ Lubricators (HJL) stands at the forefront of innovation, constantly evolving to meet these challenges. This whitepaper delves into a recent study that employs advanced Computational Fluid Dynamics (CFD) modelling to enhance the efficiency of two-stroke marine engines. The study aims to evaluate how various turbulence methods influence scavenging air dynamics and subsequently affect the interaction between oil spray and scavenging air in a two-stroke engine. Therefore, this research is significant for its potential to optimize two-stroke engine performance.

The Importance of Efficient Cylinder Lubrication

Efficient lubrication is paramount in ensuring the longevity and performance of two-stroke marine engines.

The key benefits include:

Minimizing wear and friction to prevent engine damage.

Reducing oil consumption and ash content, contributing to environmental sustainability.

Enhancing compliance with emission standards is crucial in meeting regulatory requirements.

The challenge lies in achieving optimal oil distribution and scavenging efficiency in varying operational conditions

Advanced CFD Modelling Techniques

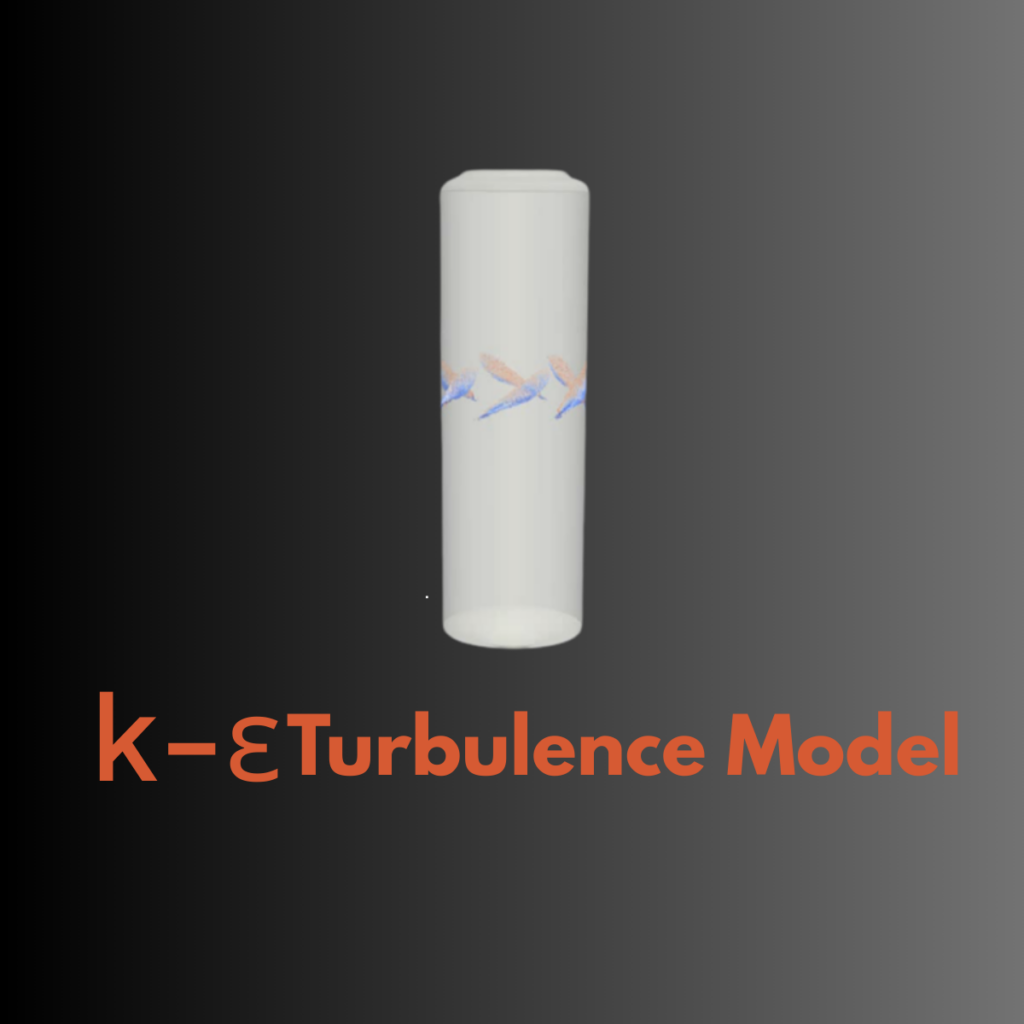

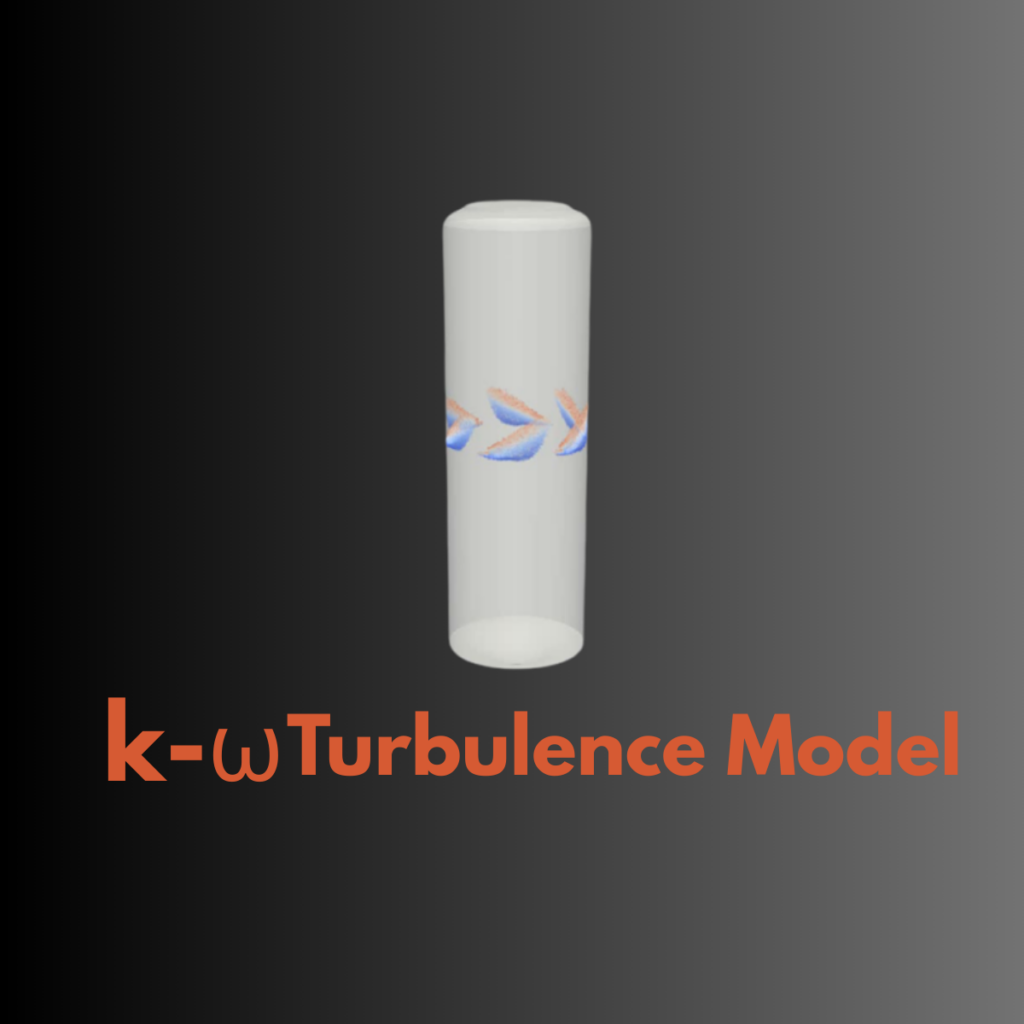

This section introduces turbulence models – specifically k-ε and k-ω—and their role in simulating the complex interactions between scavenging air and oil spray.

k-ε model: Known for its robustness in predicting spray distribution and velocity fields, this model has demonstrated superior accuracy in simulating scavenging dynamics.

k-ω model: Offers precision in regions with high shear stress, but the k-ε model was found to be more effective for our case study.

Swirl Injection Principle (SIP): Explains how SIP optimizes lubrication by improving the uniformity and effectiveness of oil distribution.

Key Findings

Scavenging Air Dynamics:

The k-ε turbulence model proved to offer more accurate spray distribution and velocity profiles. Improved scavenging efficiency results in better air-fuel mixing and lower emissions.

Oil Spray Optimization:

With the k-ε model, oil distribution became broader and more consistent, leading to reduced wear in critical areas of the cylinder liner, thereby extending engine life.

Actionable & Practical Implications for Shipowners

This study’s findings have direct, actionable benefits for shipowners:

Reduced maintenance costs thanks to optimized lubrication that minimizes engine wear.

Compliance with environmental regulations, ensuring lower emissions and smoother operations.

Enhanced engine reliability and longevity, improving the total cost of ownership for fleet operators.

Conclusion: Advanced CFD modelling has proven to be an indispensable tool in enhancing engine performance and reducing environmental impact. Through continued innovation, HJ Lubricators remains committed to offering the maritime industry efficient, sustainable, and future-focused solutions.

The practical implications for shipowners include:

Improved Fuel Efficiency– Understanding the role of scavenging air and oil spray interaction in two-stroke engines can lead to better engine designs, reducing fuel consumption and operational costs.

Lower Maintenance Costs– Optimizing lubrication reduces wear and tear, prolonging engine life and minimizing repair expenses.

Enhanced Engine Performance – The study recommends using the k − ε turbulence model for more accurate simulations, which can help manufacturers design more efficient engines.

Reduced Emissions– Improved lubrication and combustion efficiency lead to lower greenhouse gas emissions, helping shipowners comply with environmental regulations.

By applying these insights, shipowners can achieve cost savings, better engine reliability, and regulatory compliance.