HJ Smartlube 4.0

Revolutionizing lubrication technology for 2-stroke marine engines.

Patented by Hans Jensen Lubricators.

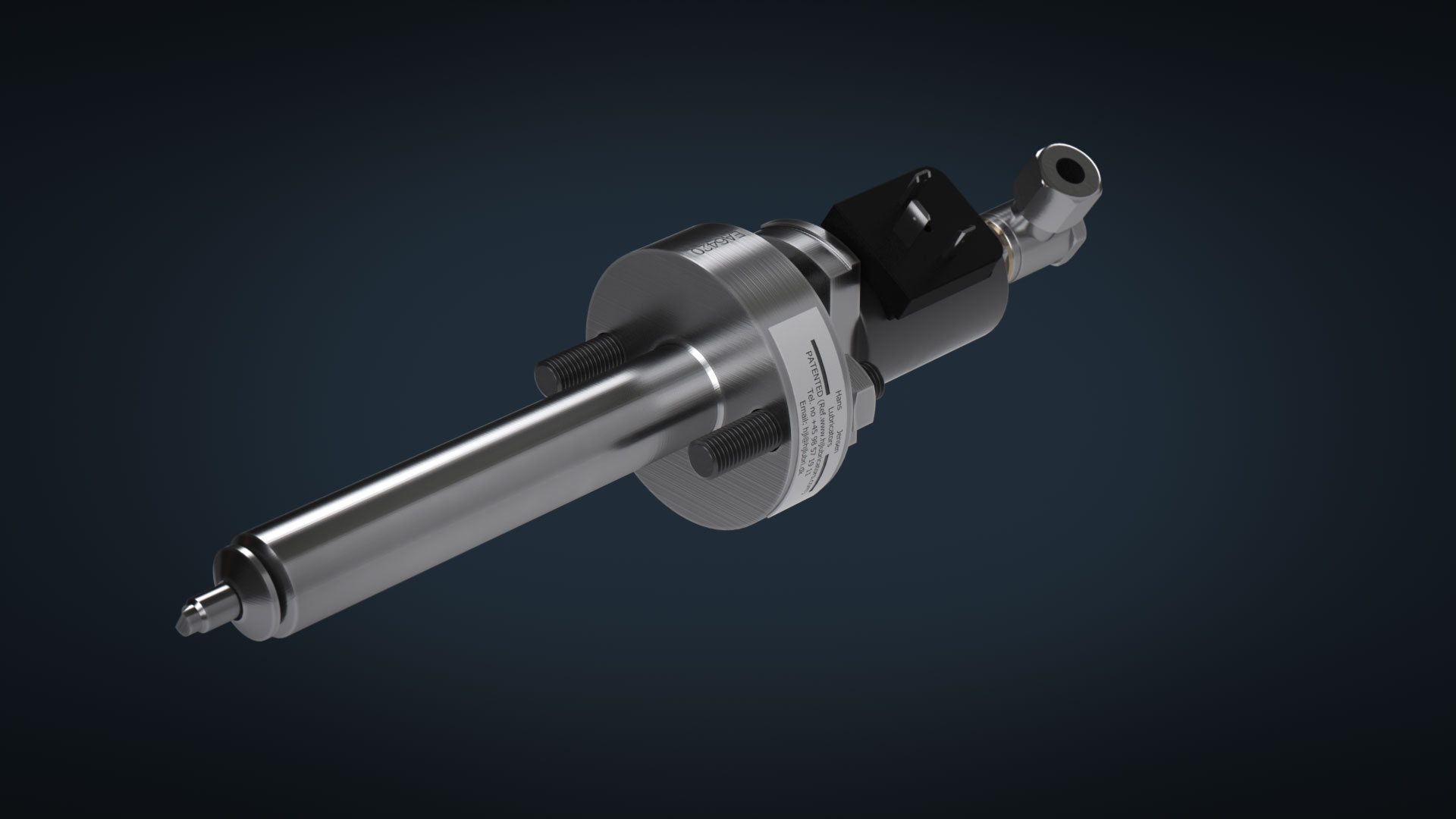

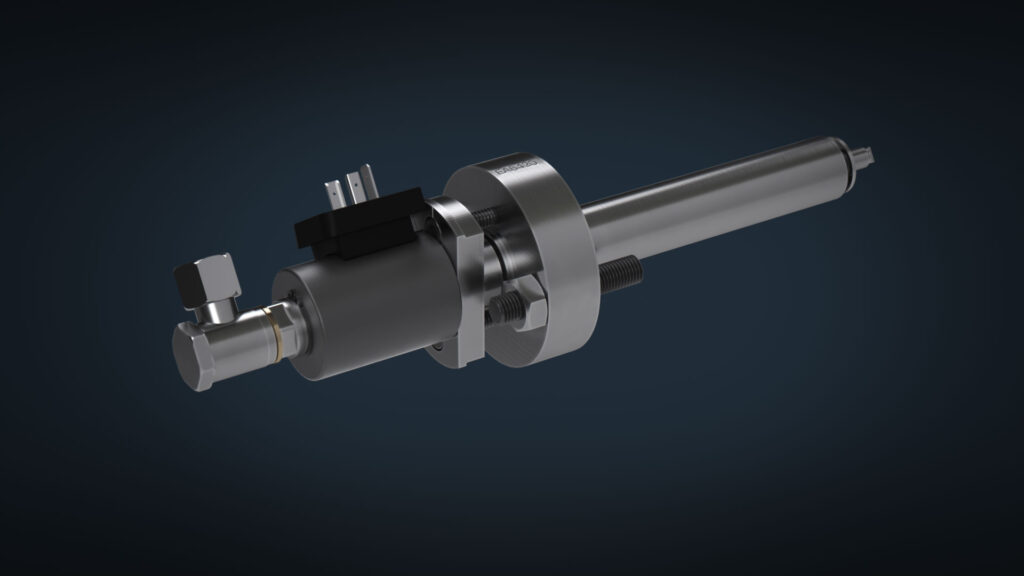

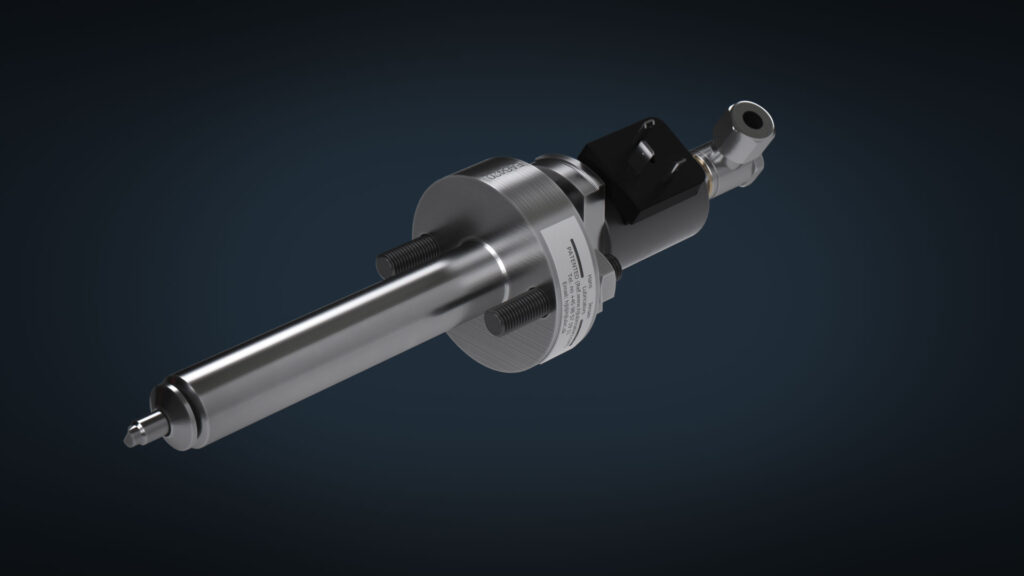

Advanced commonrail technology, integrating lubricator and valve in one compact unit.

Compact design

HJ Smartlube 4.0 is a unique combination of compact design and advanced functionality.

The system integrates the lubricator into the HJ SIP (Swirl Injection Principle) injection valve, thereby completely eliminating the need for an individual lubricator on each cylinder.

This means that the system consists of fewer parts, making maintenance and trouble-shooting faster.

Patented technology

The system injects fresh cylinder lube oil during each piston stroke to prevent wear and corrosion of the liner.

The system atomizes the cylinder oil into the combustion chamber using the scavenge air swirl at high pressure.

The result is an optimal distribution of the oil on the upper liner surface which is the most vulnerable part of the cylinder.

Get the HJ Smartlube 4.0 flyer for your convenience

BENEFITS

- Up to 60% reduction of lube oil consumption

- Reduced emission of particle matter and CO2

- Cope with future green fuels

- Improved acid neutralization and reduced corrosive wear

- Reduced wear of liners and rings

- Extended TBO

- Prepared for dual-fuel operation

- Easy operation for crew

PRODUCT FEATURES

- Oil injection in every piston stroke

- Atomizing cylinder oil into the combustion chamber

- Automatic load or sulphur dependent feed rate regulation

- Automatic Cleaning Sequence algorithm (patented technology)

- Multi-Timing algorithm periodically increases the feed rate for improved cleaning of the liner and piston

- Sulphur-, load- and BN-dependent algorithms

- Possibility for online monitoring and preventive alarms.

OPTIONAL SOFTWARE

CylinderCare Pro

Automatic Cleaning Sequence (ACS)

ACS automatically increases the injected cylinder oil quantity for a limited period of time. This “boost” of extra oil ensures optimal cleaning behind the piston rings and prevents deposit build-up. The result is improved cylinder condition and longer TBO.

The software allows for control of the frequency, timing and amount of oil injected. (Patent)

Features:

- Control the amount of extra oil injected into the ring pack

- Control frequency within a 24 hrs. cycle (typical cycle is twice a day)

- Frequency, timing and amount is customizable by engine crew

Multi-Timing

The algorithm provides multiple cylinder oil injections in a single piston stroke.

The timing combines:

1 x injection into the scavenging air swirl above the piston covering the upper liner surface to protect the combustion area.

With 1 x injection into the ring pack (combustion stroke) for enhanced cleaning and 1 x injection into the ring pack (compression stroke) for enhanced cleaning (optional).

… all in the same piston stroke!

(Patent)

Flexible injections

Volume adjustment of every injection: Every valve can individually adjust the opening time very precisely, which allows each valve to apply different feed rates. Imagine a 60-bore cylinder with 6 injection valves where it is possible to adjust different volumes at every single valve.

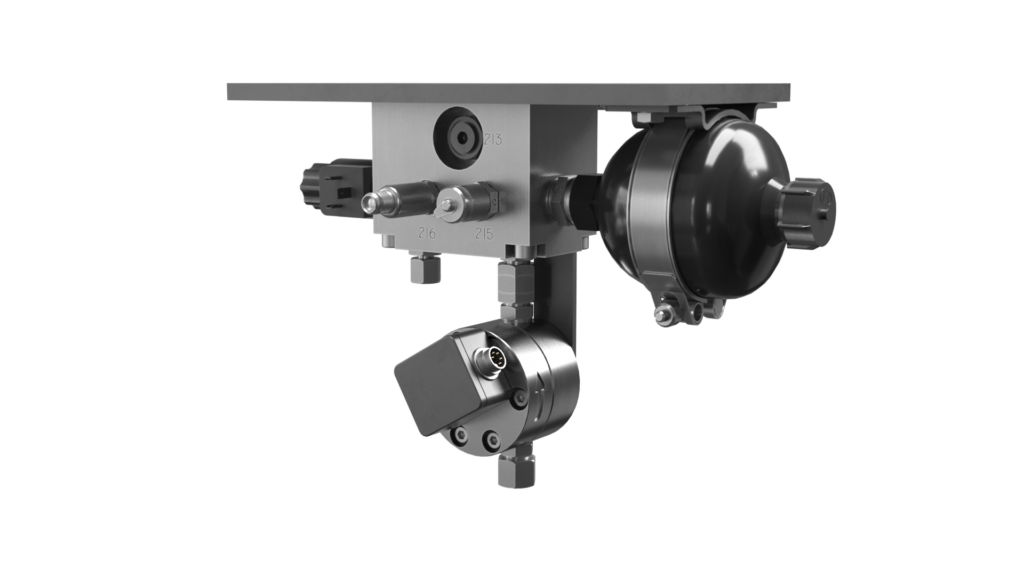

Internet-Of-Things Connectivity

The system allows remote operation through an upgradable module of the onboard computer. This allows your technical management team to ensure the correct feed rate is employed and faster trouble shooting.

Read more about HJ Smartlink here.

Would you like a detailed savings- calculation on your 2-stroke engine?

Our representative will get back to you shortly.