A partnership for efficient marine engine cylinder lubrication and operational stability

The maritime industry is facing unpredictable engine performance as the transition to low-sulfur fuels and the trend toward slow steaming introduce unforeseen wear on critical components. Engines running at lower RPMs face unique challenges, further complicating the situation. The solution lies in advanced lubrication and monitoring systems, which provide precise control over cylinder and piston maintenance, optimizing performance and preventing costly breakdowns, even in the demanding conditions of slow-speed operation.

Mandated low sulfur-fuel and more widespread fuel-saving by maneuvering at lower speeds are challenging marine engines. In 2020, the Norwegian company Ugland Marine Services AS found themselves in an unprecedented situation. Their fleet began to experience significant operational challenges.

“We started seeing frequent breakdowns in our cylinder liners and pistons. This was unusual for us, and we were faced with a highly unpredictable situation where failures occurred even shortly after overhauls,” explains Terje Olsen, Vice President Technical Department at Ugland Marine.

In search of a solution, Ugland Marine consulted various suppliers but received limited guidance. “There was a lack of understanding across the industry at the time, but we were determined to find the right solution,” says Terje Olsen.

A new approach with Hans Jensen Lubricators

In late 2020, Ugland Marine was introduced to Hans Jensen Lubricators, part of the G&O Maritime group, at a maritime conference. The two companies soon developed a working relationship, discussing ways to address Ugland’s worsening cylinder condition.

“We were fortunate to meet with Hans Jensen Lubricators, who presented us with the Lubtronic 2.0 system. This was a game changer for us,” recalls Terje Olsen.

Hans Jensen Lubricators HJ Lubtronic 2.0 is an advanced cylinder lubrication system designed to optimize oil distribution based on real-time operational parameters such as engine load and fuel type.

“Lubtronic 2.0 ensures precise lubrication, reducing the risk of both under- and over-lubrication, which is critical, especially under slow steaming conditions,” says Mads Stougård Jensen, Marine Engineer at Hans Jensen Lubricators.

The system also includes SIP valves (Swirl Injection Principle), which improve the oil distribution around the cylinder liners.

“The SIP technology provides better oil distribution and a more uniform coating, which has proved to significantly improve cylinder conditions.

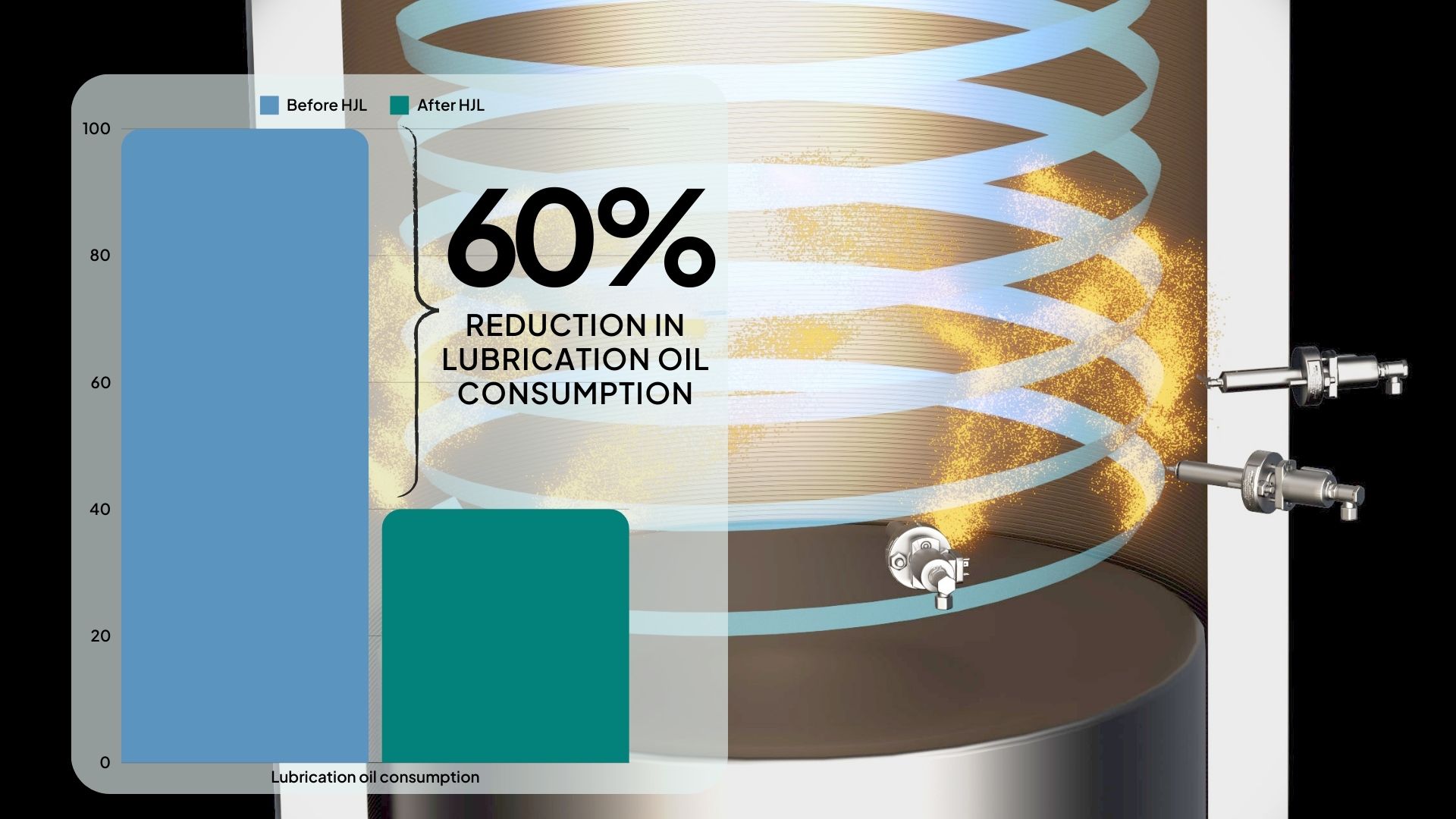

60% reduction in lubrication oil

The installations were gradually completed across 12 ships, with Ugland selling two vessels before the system could be implemented fleet wide. The first ship was fitted in March 2022, and the final installation was completed by September 2024.

Since the system’s installation, Ugland has witnessed significant improvements in both cylinder condition and overall performance. “We’ve achieved about a 60% reduction in lubrication oil consumption, which is substantial given the rising costs of lubrication oils. More importantly, the system has stabilized operations, particularly under slow steaming, where we previously faced unpredictable failures,” Terje Olsen remarks.

The introduction of a monitoring system has also been a part of the operational overhaul.

“We now receive detailed reports from oil samples taken from the cylinders, allowing us to monitor wear levels, soot, and metal content in real-time. This data is shared with Hans Jensen Lubricators, who serve as a third-party verifier, ensuring we get the most accurate analysis possible,” says Terje Olsen.

With the data-driven insights provided by the monitoring system, Ugland Marine can make informed decisions about maintenance intervals, significantly reducing unplanned downtime.

“It’s not just about saving on oil; it’s about preventing failures that would otherwise lead to costly repairs and lost operational time,” adds Mads Stougård Jensen.

Building on the success of the Lubtronic 2.0 and SIP valves, Ugland Marine has plans to continue the collaboration with Hans Jensen Lubricators.

“We’re planning to install the system on two new vessels currently under construction,” Terje Olsen says. “Although engine manufacturers have been hesitant, particularly regarding warranty concerns, we’ve decided to install the system after the warranty period expires. This is part of our long-term strategy to ensure operational efficiency.”