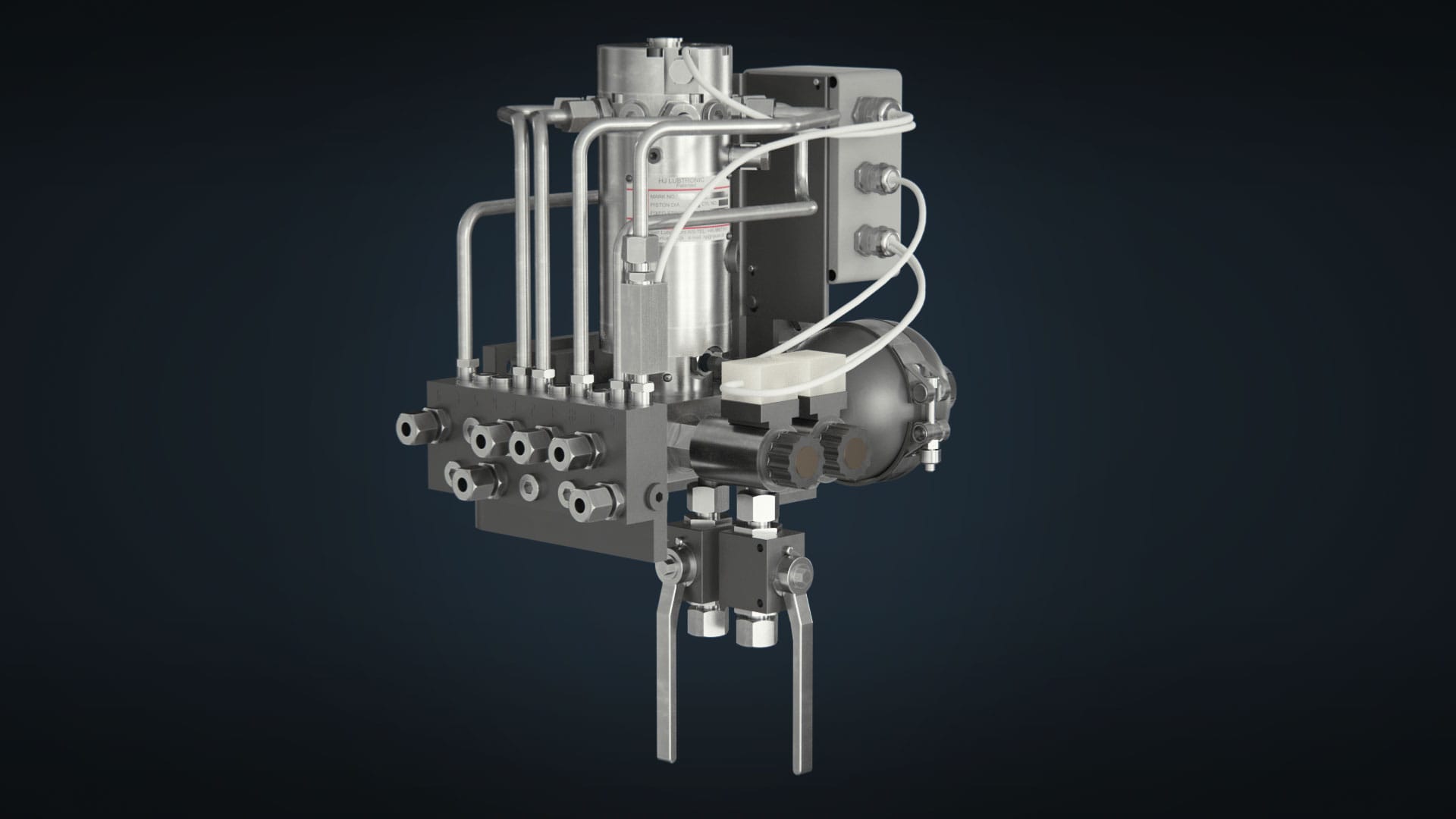

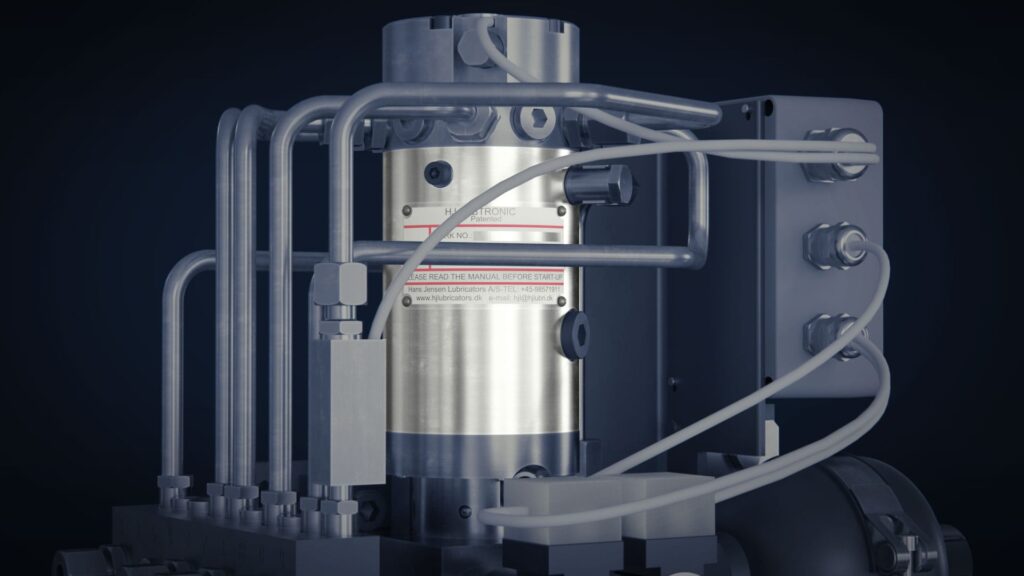

HJ Lubtronic 2.0

Electronically controlled cylinder lubricator injecting fresh cylinder oil during each piston stroke.

Reduce cylinder lube oil consumption by up to 50% and prevent cylinder liner wear and cold corrosion.

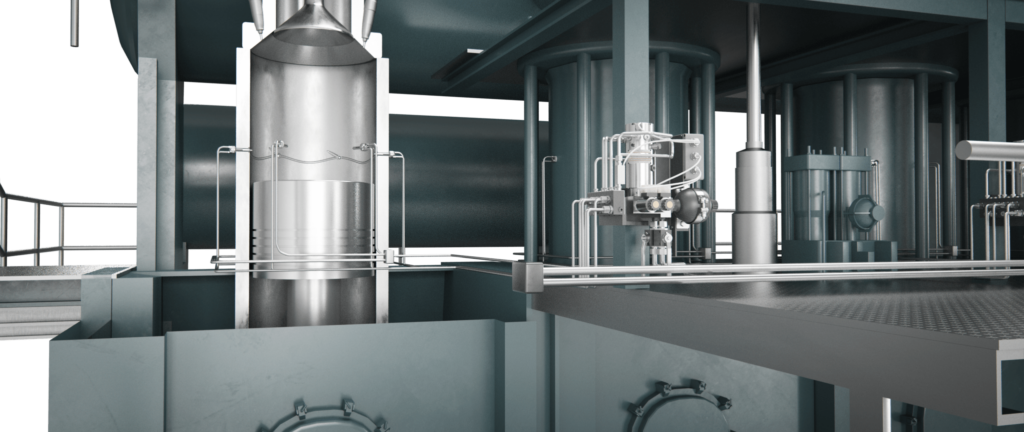

Introduction to HJ Lubtronic 2.0

HJ Lubtronic 2.0 is an electronic lubricator that adjusts feed rate according to ME load, BN number or sulphur content of the fuel oil.

This effectively reduces cylinder oil consumption and optimizes cylinder condition and engine reliability. The system is simple to operate by the crew on our user-friendly HMI.

The patented HJ Lubtronic 2.0 is able to inject fresh cylinder in every engine revolution – even at low load operation (slow steaming).

This is crucial to effectively protect against abrasive and corrosive wear while operating for optimal EEXI compliance.

Benefits

- Up to 60% reduction of cylinder oil consumption

- Reduced emission of particle matter and CO2

- Improved acid neutralization and reduced corrosive wear

- Reduced wear of liners and rings

- Extended TBO

- Easy operation for crew

Product features

- Oil injection in every piston stroke

- Atomizing cylinder oil into the combustion chamber

- Automatic load or sulphur dependent feed rate regulation

- Automatic Cleaning Sequence algorithm (patented technology)

- Delta-Timing algorithm ensures lubrication both into the ring pack and liner

- Sulphur-, load- and BN-dependent algorithms

- Possibility for online monitoring and preventive alarms

Download the Lubtronic 2.0 flyer for your convenience

CASE STUDY: “K” LINE BULK SHIPPING

Slices feed rate by 55%

“K” Line Bulk Shipping bought the HJ Lubtronic 2.0 SIP system for a total of 10 vessels. Feed rates of 0.5 g/kWh have been achieved since installation on both MC and ME engines, as well as improved cylinder conditions.

OPTIONAL SOFTWARE

CylinderCare Pro

Delta-Timing

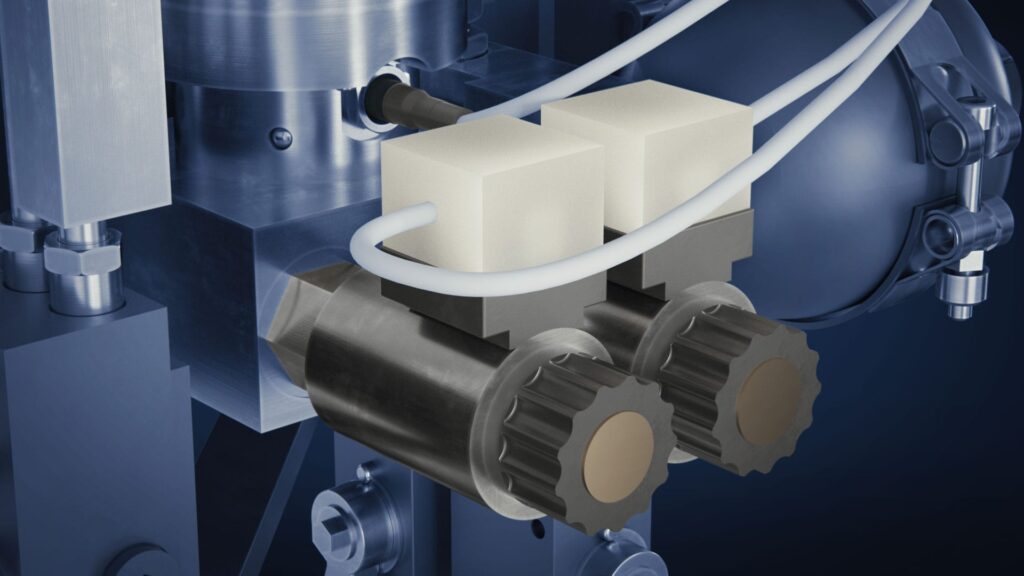

On each engine revolution, the Delta-Timing algorithm can change the crankshaft angle at which cylinder oil is injected.

This can be customized to your needs. For example, if the algorithm is set to inject 40% in the ring pack and 60% according to SIP timing, the algorithm will inject 2 full injections into the ring pack and 3 full injections according to SIP timing over a total of 5 revolutions, as 2/5 = 40% and 3/5 = 60%.

(Patent)

Automatic Cleaning Sequence (ACS)

ACS automatically increases the injected cylinder oil quantity for a limited period of time. This “boost” of extra oil ensures optimal cleaning of liners and rings from particles and deposits which in the long run leads to improved cylinder condition. (Patent)

Features:

- Control the amount of extra oil injected into the ring pack

- Control frequency within a 24 hrs. cycle (typical cycle is twice a day)

- Frequency, timing and amount is customizable by engine crew