SERVICE LETTER

Feed rate adjustment

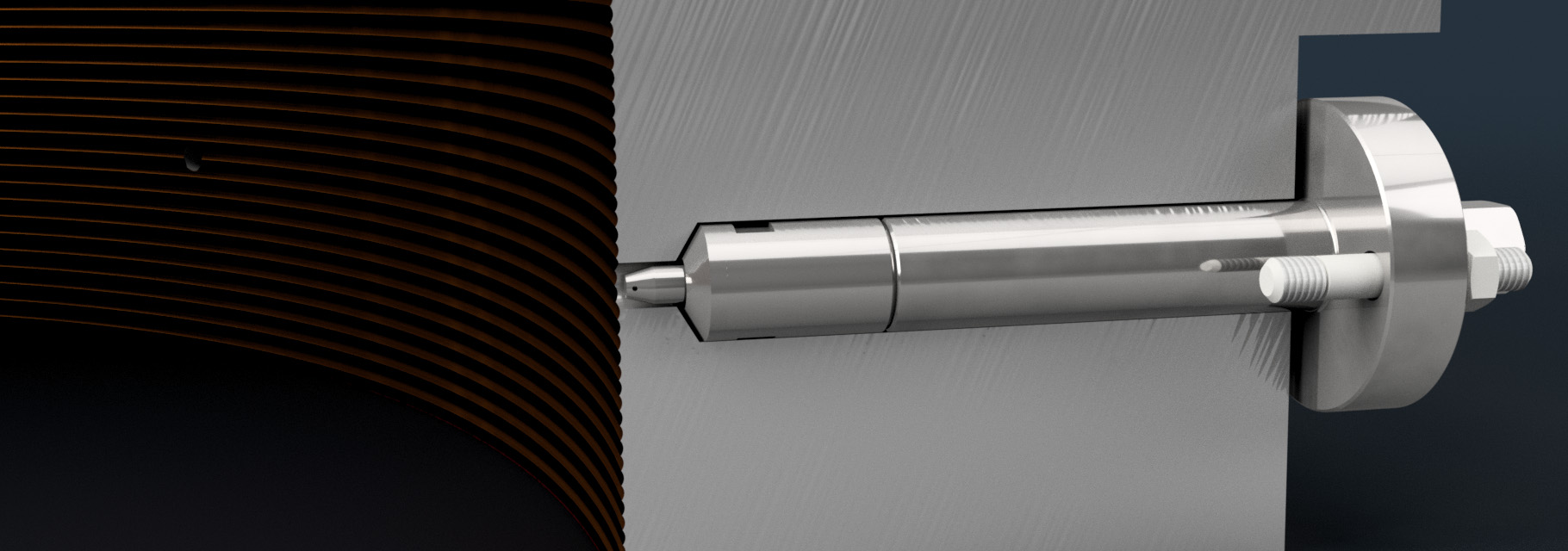

after installing HJ Non-Return valves

MAY 2015

Relevant for HJ Non-Return valve users

Feed rate adjustment

The purpose of this Service Letter is to guide the user in optimizing the cylinder oil feed rate, so the full saving potential and better cylinder condition made possible by the Hans Jensen’s Non-Return valves can be realized.

Please contact our After Sales department for further information and scheduling a visit by our engineer.

T: +45 9857 1911

E:

After completing the installation of the HJ Non-return cylinder lubrication system without overhauling the piston and/or changing the cylinder liner, we recommend to adjust the cylinder oil feed rate to be as follows:

From departure to first available port inspection or to minimum 100 running hours: 1.00 g/kWh

lf the cylinder condition during the port inspection is found to be satisfactory, the feed rate may be reduced by 0.10 g/kWh to 0.90 g/kWh.

Depending on engine type and engine general condition further reduction is possible, however only atter a satisfactory port inspection and minimum 100 running hours, the feed rate can be reduced by steps of eg. 0.05 g/kWh down to target feed rate.

With a sulphur content between 1.5 % – 3.5 % and a cylinder oil with TBN 70 we recommend target feed rates down to 0.6 g/kWh, with a sulphur content beneath 1.5 % target feed rate can in some case be reduced to a level below 0.6 g/kWh

It is recommended that scrape downs are analysed for iron wear partides and TBN residues for evaluation of further reduction, either by using on board equipment or at a laboratory.

You are always welcome to consult us in case you have questions or are in doubt about the condition of your cylinders. We should be pleased to place our knowledge and experience at our disposal.

lf vessel before installation of HJ System had a lower feed rate then 1.0g/kWh, the feed rate can be set below 1.0 g/kWh. Please remember that HJ only can give recommendations regarding feed rate. It is always user responsibility to keep the best possible cylinder conditioning, and HJL cannot be held responsible for any damages of any kind.

Please download the PDF for more accurate guidance.