SERVICE LETTER

Feed rate adjustment after a HJ SIP installation

OCTOBER 2016

Relevant for users of HJ SIP valves

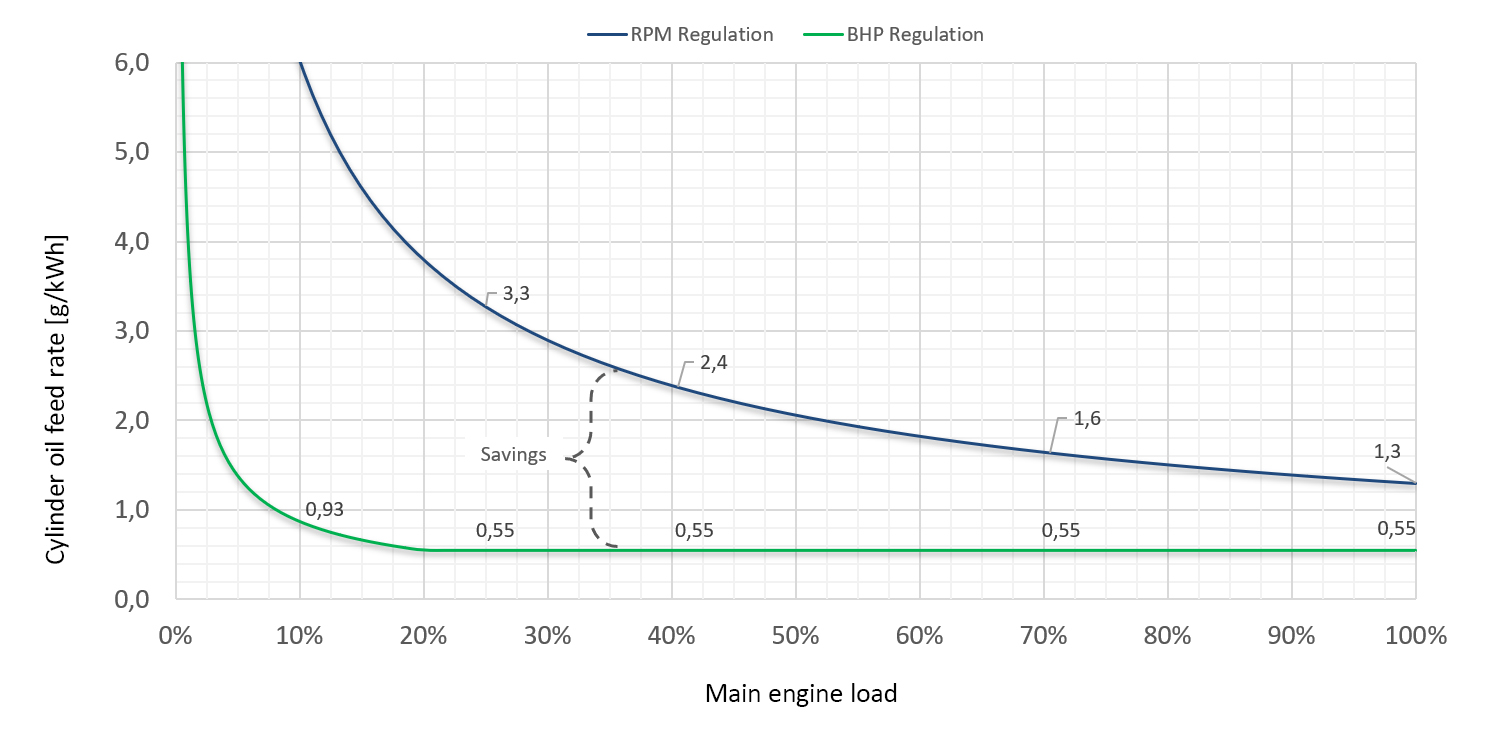

The purpose of this Service Letter is to guide the user in optimizing the cylinder oil feed rate, so the full saving potential and better cylinder condition made possible by the Hans Jensen’s Swirl Injection Principle (HJ SIP) valves can be realized.

Please contact our After Sales department for further information and scheduling a visit by our engineer.

T: +45 9857 1911

E:

Feed rate adjustment

After completing the installation of the HJ SIP cylinder lubrication system without overhauling the piston and/or changing the cylinder liner, the cylinder oil feed rate may be adjusted as follows:

From departure to first available port inspection or to minimum 100 running hours:

0.90 g/kWh.

lf the cylinder condition during the port inspection is found to be satisfactory, the feed rate may be reduced by 0.10 g/kWh to:

0.80 g/kWh.

Depending on engine type and engine general condition further reduction is possible, however only atter a satisfactory port inspection or minimum 100 running hours, the feed rate can be reduced in steps of 0.05 g/kWh down to:

0.60 g/kWh.

lf you are already running at a lower feed rate please use this feed rate as your starting point.

Further reduction may be possible, but this will require strict and continual monitoring of the cylinder condition by an attentive and competent crew.

The above-mentioned feed rates are based on cylinder oil with BN 70 and fuel oil with a sulphur content between 1.5 – 3.5 %.

It is recommended that scrape downs are analysed for iron wear particles and BN residues for evaluation of further reduction, either by using onboard equipment or at a laboratory.

Please down the PDF for more detailed guidance.