SERVICE LETTER

How to succeed with HJ SIP valves

SEPTEMBER 2018

Relevant for users of HJ SIP valves

The purpose of this Service Letter is to guide the user in optimizing the cylinder oil feed rate, so the full saving potential and better cylinder condition made possible by the Hans Jensen’s Swirl Injection Principle (HJ SIP) valves can be realized.

Please contact our After Sales department for further information and scheduling a visit by our engineer.

T: +45 9857 1911

E:

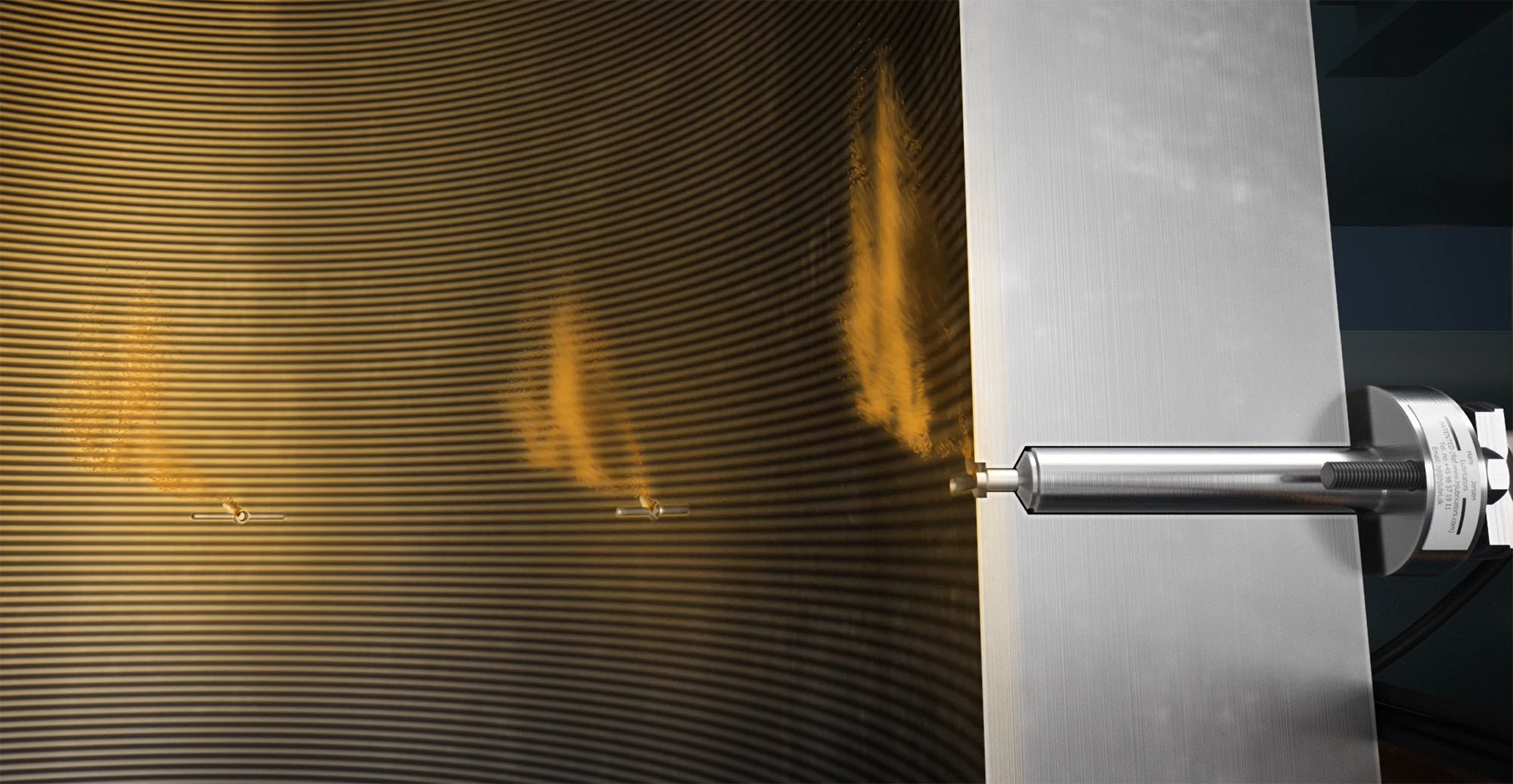

The main challenge of cylinder lubrication is a general issue, independent of operating conditions. It is to get the cylinder oil to the top of the liner. To lubricate a cylinder effectively, oil and additives are needed on the whole liner surface, that is in contact with the piston rings. However the top of the liner needs more of both oil and additives.

The reasons are:

Firstly, lubrication regime will move from hydrodynamic to boundary lubrication, due to the low piston speed at, or close to Top Dead Center (TDC).

Secondly, the acids formed during combustion primarily condensate in the top.

Finally, oil degradation is a bigger problem at the top due to the higher temperature. The top is also the most critical part of the cylinder because the pressure is at its highest, when the piston is around TDC.

A good seal between the piston rings and the liner wall is critical here, to avoid blow-by gasses and to effectively convert the thermal energy of the combustion into the mechanical energy of the piston.

Please download the PDF for more extensive information.