Improve cylinder condition through effective lubrication

Cylinder condition is a critical factor that affects the performance and longevity of marine engines. Proper lubrication is essential to ensure optimal cylinder condition and prevent wear and damage. In this blog post, you can learn more about the importance of cylinder condition monitoring and how much cylinder wear is acceptable.

Cylinder condition monitoring

Cylinder condition monitoring involves regular inspections of the cylinder liners, piston rings, and other components to assess their condition and identify potential issues. This can help prevent major failures and prolong engine life. There are various methods for cylinder condition monitoring, including visual inspections, wear measurements, and oil analysis.

The role of lubrication in improving cylinder condition

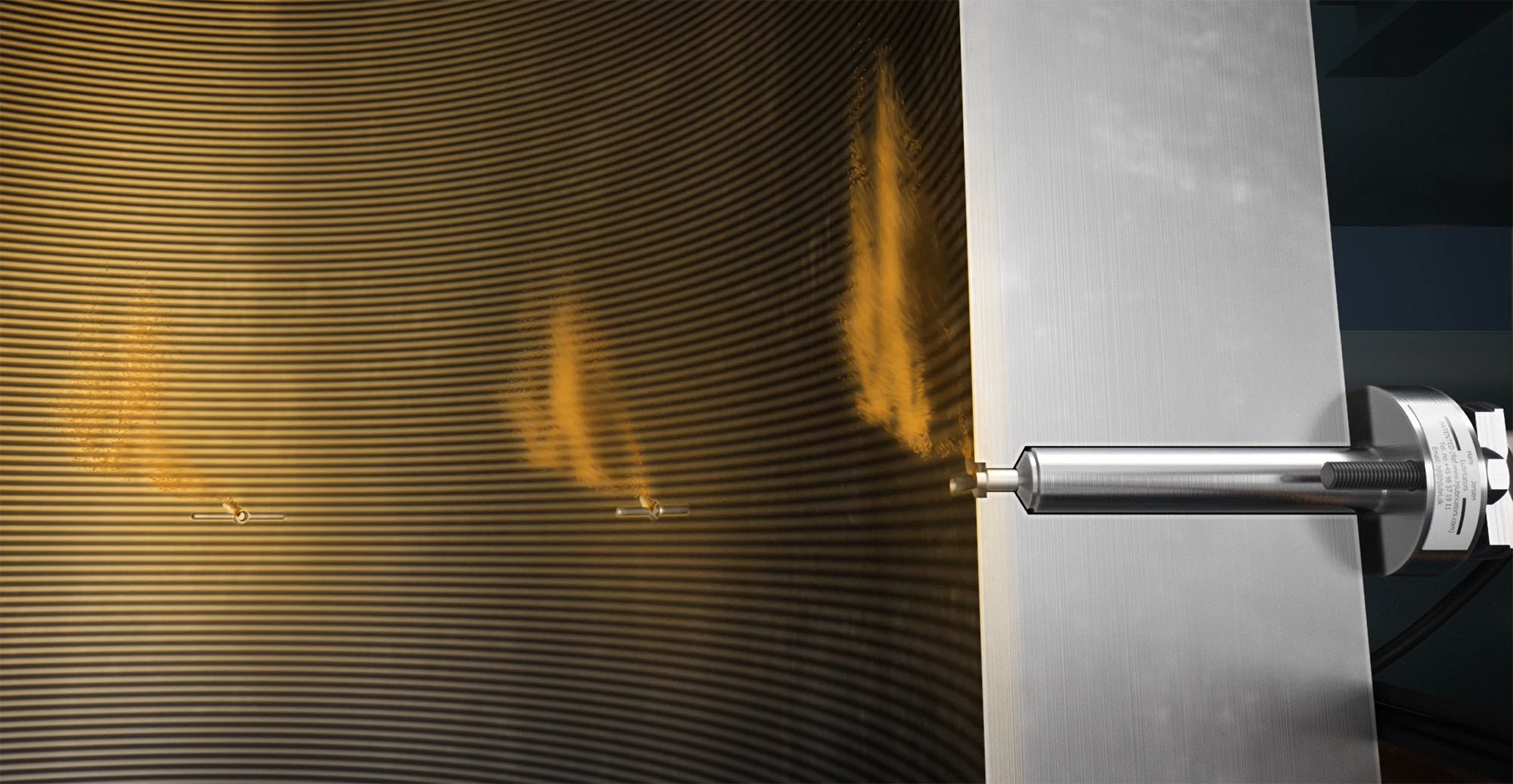

Efficient cylinder lubrication reduces the friction between the piston rings and the liner which preserves fuel. This also minimizes the wear inside the cylinder which extends TBO. Then there is the distribution of the lubricant inside the cylinder, which is important, because it helps neutralize acids forming during combustion. Furthermore proper lubrication cleans the cylinder from deposits and maintains a gas tight seal for better engine efficiency.

For more information: please go to Services

Electronically controlled lubrication improves cylinder condition

Our electronic lubrication system improves cylinder condition by ensuring consistent and precise lubrication in every piston stroke. These systems can deliver the right amount of lubricant to the right place at the right time, reducing the risk of over- or under-lubrication. By minimizing the risk of cylinder wear and damage, automatic lubrication systems will strengthen cylinder condition, help prolong engine life and reduce maintenance costs

How much cylinder wear is acceptable?

The amount of cylinder wear that is acceptable depends on several factors, including:

- Engine type

- Operating conditions

- Maintenance practices

Generally, a wear rate between 0.05 – 0.1 mm per 1000 running hours is considered acceptable for most marine engines. However, some engines may have tighter tolerances, and a lower wear rate may be necessary to maintain optimal performance.

CASE: Learn about how HAFNIA tripled liner lifetime

Hans Jensen Lubricators’ patented solutions

We are committed to delivering innovative and effective solutions to our clients. That’s why we have developed patented lubrication systems that significantly improve your cylinder condition, engine performance and efficiency. Our solutions are based on 100 years of research and development, and they have been tested and proven in real-world applications.

Our patented systems convert RPM-dependent to load-dependent cylinder lubrication and a two-stroke engine lubrication system that can help reduce emissions and lube oil consumption. By leveraging our patented solutions, our clients can benefit from an improvement in cylinder condition, enhanced engine performance, reduced maintenance costs.

Our team is ready to help you and answer questions you might have.